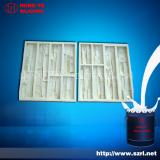

1. RTV-2 silicon for artificial stone ( Tin condensation series) application:

RTV silicone can be used for production of different sizes of polyurethane moulds,gypsum moulds,plaster moulds, resin moulds,polyresin moulds,PU resin moulds,wax moulds,stone moulds ,epoxy moulds,acrylic moulds,polyester moulds making

A. Decorative items: cornices moulding ,columns moulding,ornaments moulding,statues molding.....

B. Casting of funiture and decoration crafts molding

C. Construction: prefabrication of decrative features molding,pavement molding,paving stone moulding,urban

furniture molding,concrete products molding

D. Soap moulding,candles crafts moulding,toys moulding,sculpture moulding

2. RTV-2 silicon for artificial stone ( Tin condensation series) of TDS:

Model

630#

Appearance

white

Mixing ratio (%)

5%

Operating time ( hours )

30~40

Curing time( hours )

3~4

Hardness (A°)

30

Density ( g/cm 3)

1.08

Viscosity (25 C°,mPa.s)

22000~ 24000

Tensile-strength

( kgf/cm2 )

40

Tear-strength (kgf/cm )

25

Elongation-break(%)

≥ 420

Retractility(%)

≤0.25

3. RTV-2 silicon for artificial stone ( Tin condensation series) main features:

1. Good characteristics of easy-operation

2. Light viscosity and good flowability

3. Low shrinkage

4. Excellent tensile and tear strength

5. Favorable hardness

6. High temperature resistance, acid and alkali-resistance and ageing resistance

7. High duplication times

4. RTV-2 silicon for artificial stone ( Tin condensation series) frequently asked question:

Why does the silicone rubber molds appeared striately and unsmoothly?

It is because the appearance of the product or the model itself is not perfect, and it has not been polished before the further operation. So when you make silicon molds, firstly you should polish the product, spray the mold spray evenly on the product. In this case, the problem can be avoided.

To recommend suitable product for your application, we would be much appreciated to have your following information:

1. What is the material of your product?

2. What is the size of your product?

3. How do you make silicone mold, by pouring or brushing?

Any questions of RTV-2 silicon for artificial stone ( Tin condensation series), please feel free to

contact Crystal:

TEL: 086-755-89948294

FAX: 086-755-89948030

MOBILE:086-18938867509

RTV-2 silicon for artificial stone ( Tin condensation series)

E-mail:

E-mail: